All published articles of this journal are available on ScienceDirect.

Bruise Damage Susceptibility and Fruit Quality Assessment of Pear

Abstract

Introduction:

Bruising is a type of mechanical damage that challenges fresh horticulture production efforts, which occurs mainly due to excessive compression and impact forces during postharvest operations resulting in quality deterioration of fresh produce and reduction in economic value.

Objective:

This study aims to assess the bruise susceptibility of imported pears and determine its effect on pear quality attributes.

Materials and Methods:

Each Pyrus communis, variety ‘D'Anjou’ imported pears was impacted by a known mass steel ball at three different drop heights (20, 40, and 60 cm). Bruised fruit was stored at 22°C with 45±5% RH and 10°C with 85±5% RH for 48 hours storage period. Pears were also subjected to different quality analyses like color, firmness, weight loss, and total soluble solids (TSS). The analysis was conducted by performing two factorial balanced analyses of variance (ANOVA).

Results:

Bruise area, bruise volume, and bruise susceptibility were the highest at higher drop impact (60 cm) on pears stored at 22°C and the lowest were at lower drop impact (20 cm) on pears stored at 10°C. Furthermore, there was a statistically significant impact of drop height and temperature on bruising susceptibility. Besides, statistics showed a significant impact of the studied factors (temperature and drop height) on quality parameters of pears such as lightness (L*), redness-greenness (a*), weight loss, and firmness after 48 hours of storage

Conclusion:

Mechanical damages like bruising can be affected by many factors like storage temperature and impact level force. Finally, it was concluded that mechanical damages like bruising can be affected by many factors like storage temperature and impact force. Overall, this study can consider as a guideline for workers during postharvest operations and handling.

1. INTRODUCTION

Pear (Pyrus species) is one of the oldest crops have been cultivated by human beings. Pear fruit is consumed globally and can be also utilized as a processed product like drinks, jam, and dried preserved fruit [1]. Currently, the pear has become one of the attractive fresh produce in food research and industry as an excellent source of some beneficial compounds that help to prevent from cardiovascular diseases [2]. High sugar content is almost the main important factor in pear fruit [3]. The texture of pear is another quality parameter linked with a pear variety which depends on its flesh cell specification and other different factors like cell wall strength and thickness, cell size, and water content [2]. Furthermore, pear can be kept in cold storage conditions for a long time with minimum deterioration, development, and internal damages [3]. Moreover, pears are extremely perishable fresh produce compared to apples as they are sensitive against postharvest operations like harvesting, reloading, handling, and transport [4].

It has been estimated that about 30% to 40% of fresh produce undergo postharvest quality and quantity losses from the time of harvesting to the market [5]. Consumers mainly judge the quality of fresh fruits based on their appearance [6] as well as the amount of bruising which can reduce consumer acceptance and value reduction. Bruising is a common problem along the marketing chain of many fruits and vegetables, which can cause physical defects [7], leading to postharvest losses [2]. Bruising is well-known as damage to plant tissue caused by external forces, compression and impact, resulted in physical alteration (texture) and chemical changes (color and flavor). Therefore, it can cause high economic losses due to the rejection of the damaged produce by consumers [8].

Fresh products are susceptible to bruise particularly when they contact each other or against rigid surfaces during the time of picking and within the operations of the postharvest supply chain like transportation and handling. Cell breakage is the physical indication of bruising that leads to the release of enzymes like cytoplasmic enzymes to the intercellular space [9]. The most important cause of bruising damage during postharvest activities are impact and compression forces [10]. Several studies have attempted to find a correlation between bruising damage and mechanical parameters like loading force [2], drop height [11], impact surface [8], etc. Most of the studies related to bruising are commonly linked with soft rind fruits like kiwifruit [12], pear [13], apple [14], peach [15], and tomatoes [16].

The physiological process like moisture loss and respiration can occur in freshly harvested fruits affected by bruise damage [17]. Furthermore, metabolic process changes that occur due to bruise damage like transpiration and respiration can lead to spoilage, mass loss, shrinkage [18]. Temperature is one of the major factors that influence the bruising of fruits [9]. Therefore, this paper aims to study the bruise susceptibility of imported pear fruits (D'Anjou variety) at different storage temperatures using three different impact energy levels and to evaluate the response of quality attributes of pears as affected by the resulted bruising during short term storage period.

2. MATERIALS AND METHODS

2.1. Fruit Preparation

Fruits of ‘D'Anjou’ pear were procured and transported from the market to the Postharvest Technology and Quality Management laboratory at the Sultan Qaboos University, Sultanate of Oman. Fruits were categorized for uniformity of shape, size, weight (159.69 ± 4.09 g), color, and free from decay or mechanical injuries. Pear fruits were divided equally and stored at 22°C (45±5% RH) and 10°C (85±5% RH) as recommended by Bodner and Scampicchio [19] and Kader et al. [20], respectively for 48 hours to allow bruise sign to appear on damaged tissue [11] of pears after the drop impact test. Each storage condition consists of 3 groups (treatments) where each of them includes 3 replicates.

2.2. Bruise Measurements Evaluation

Impact bruising of selected pears was done by applying the drop test method described by Hussein et al. [11] (Fig. 1). Nine pears from each storage temperature condition were bruised by dropping a steel ball impactor of a known mass (66.05 g) from heights of 20 (low), 40 (medium), and 60 (high) cm through a hollow PVC pipe onto the pear (3 replicates per drop height). Before storage, the bruised area of the samples was marked for bruise recognition during bruise measurement. Pears were sliced from the centre of the marked area and the existence of bruise was recognized by the presence of damaged tissue which was identifiable from another unbruised region of the same fruit. As shown in Fig. (2), bruise dimensions were measured, bruise widths (w1 and w2) and bruise depth (hb), were measured using a digital venire calliper (Model: Mitutoyo, Mitutoyo Corp., Japan). The size of bruise damage was described as bruise area, mm2, (Eq. 1), bruise volume, m3 (semi-oblate), (Eq. 2) [8], bruise impact energy, J, (Eq. 3) and bruise susceptibility, m3/J, (Eq. 4) [11].

|

(1) |

|

(2) |

|

(3) |

|

(4) |

Where w1 and w2 are major and minor width (mm) respectively, d is the diameter (mm), hb is the depth of the bruise, mb is steel ball mass (66.05 g), g is the acceleration due to gravity (9.81 m s−2) and h is the drop height of the ball (cm). In this study, the impact energies for each drop height were 0.129 J (20 cm), 0.259 J (40 cm), and 0.388J (60 cm), respectively. The impact energies are within the threshold of energies that can cause damage to pears, as recorded by Lipa et al. [21]

2.3. Color Characteristic of Pears

The pear fruit color was measured by utilizing a colorimeter (Model: CR-310, Minolta, Japan) and expressed by the L*a* b* color coordinates (CIELAB color space). L* refers to lightness, a* and b* indicate redness-greenness and yellowness-blueness, respectively. Color measurements were replicated 6 times for each pear sample. Chroma (Eq. 5) and hue (Eq. 6) were also calculated from L*, a*, and b* values using the following equations [22]:

|

(5) |

|

(6) |

2.4. Weight loss, Firmness, and Total Soluble Solids (TSS)

To identify the weight loss of pear fruit after subjected to bruise damage, each pear from each storage condition (10°C and 22°C) was weighed before the test and after 48 hours storage using an electric weight balance (Model: GX.4000, Japan). A hand penetrometer (Model: FT 327, EFFEGI, Italy) was used to determine the firmness reduction percentage of the fruit. Furthermore, Total Soluble Solids (TSS) of the pear fruit were obtained by using a hand-held refractometer which was calibrated at 20oC and expressed at °Brix [23].

2.5. Statistical Analysis

All statistical analyses were performed using SPSS 20.0 (International Business Machine Crop., USA) software. A two-factorial analysis of variance (ANOVA) was performed to evaluate the effect of storage temperature and different drop heigh levels (impact forces) on pear fruit bruise area, volume, and susceptibility. Effect of storage and impact energy on other quality attributes of pears, such as color, weight loss, firmness, and TSS, were also analyzed. Main treatment means were compared using Tukey’s range (HSD) test (p<0.05). All results were expressed in mean ± standard deviation (S.D). Bar charts were constructed using GraphPad Prism software version 9.1.0 (GraphPad Software, Inc. San Diego, USA).

3. RESULTS AND DISCUSSION

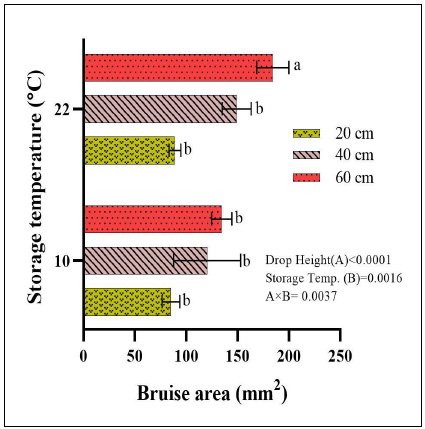

3.1. Bruise Size Measurements Affected by Drop Height and Temperature Condition

The results showed that the bruised area and volume of pears were significantly influenced by drop height (p<0.0001) and storage temperature (p<0.0001) after 48 hours storage period (Figs. 3 and 4). The mean of bruise area and volume of pear bruised by an impact from 60 cm drop height and stored at 22°C differed significantly with bruised pear’s means stored at both storage conditions (Figs. 3 and 4). Combined average bruise area and volume of pears stored at 10 and 22°C showed that pears impacted with a steel ball from 60 cm (0.388 J) had higher bruise area and volume than those impacted from either 40 cm (0.259 J) and 20 cm (0.129 J), respectively. High impact level (60 cm) and storage at room temperature recorded the highest bruise area and volume with 184 mm2 (Fig. 3) and 4.75

The bruise susceptibility was varied significantly with storage temperature (p<0.0001) and drop height (p<0.0001) for 48 hours storage period (Fig. 5). The mean value of bruise susceptibility for 60 cm (0.338 J) bruised pears at room temperature storage condition (22°C) was statistically varied with other bruised pears at both storage conditions. The bruise susceptibility of high impact bruised pears (60 cm) and stored at room temperature was higher (1.25×10-3 m3 J-1) compared to those stored at 10°C (5.11×10-4 m3 J-1) after 48 hours storage. Storage at room temperature showed a higher increase in the bruise susceptibility of pear impacted from 40 and 20 cm with 9.82×10-4 and 4.09×10-4 m3 J-1, respectively. While, medium (40 cm) and low (20 cm) drop heights showed a bruise susceptibility with 4.94×10-4 and 2.95×10-4 m3 J-1 at 10°C, respectively. Overall, bruise susceptibility and severity were increased as impact energy, drop height, and storage temperature increased.

These findings are similar to the study of Lu et al. [24] and Hussein et al. [25], where bruise area and volume can be elevated with the increase in drop height which is directly increase the impact energy of each height. Similar results were reported for peach [26], apple [14], and pomegranate [11, 25]. Besides, the current study results agree with a study in peach where the high-temperature condition can cause more incidence of bruising due to the active state of enzymes that degrade the cell wall resulted in stiffness on mechanical damaged fresh produce [27]. Also, Shafie et al. [28] reported that increasing refrigerated storage temperature can decrease bruise damage of pomegranate. It was also recorded by Bugaud et al. [29] that reducing the temperature from 18°C to 13°C decreased bruise susceptibility of bananas. As reported by Cui et al. [30], the degree of fresh produce bruising at ambient temperature was higher and severe than the storage at 10°C.

3.2. Color Characteristic of Pears

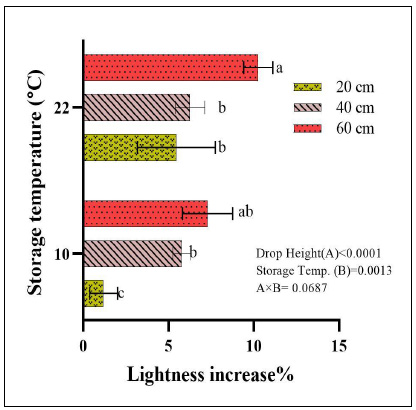

The L* (lightness) value of pear fruits was significantly influenced by the drop height (p<0.0001) and storage temperature (p=0.0013) (Fig. 6). The L* value increment % (mean ± Sd) was highly observed on pear impacted by an impactor from 60 cm drop height followed by 40 and 20 cm drop height at both storage conditions. Pears impacted by a steel ball from 60 cm drop height and stored at 22°C showed a 10.25% greater L* reduction than those stored at 10°C by 7.29%. After 48 hours of storage, pears impacted from 20 cm drop height and stored at 10°C was varied significantly with all bruised pears (20, 40, and 60 cm drop heights) at both storage conditions and recorded the lowest L* reduction percentage by 0.12%.

Table 1 presents the values of a*, b*, Chroma, and hue (mean ± Sd) of pears impacted by an impactor from different drop height levels (20 cm, 40 cm, and 60 cm) stored at 10°C and 22°C for 48 hours of storage period. A significant difference was found between the investigated factors like drop height (p=0.04567) and storage temperature (p=0.02870) and a* (redness-greenness) value of pear (Table 2). At 22°C storage condition, the highest drop height (60 cm) with an impact energy of 0.388 J recorded a double increase on a* value compared to 40 cm and 20 cm drop heights after 48 hours storage. A similar trend was observed on a* value of pear stored at 10°C. The lowest impact energy (0.129 J) generated from the drop height of 20 cm produced no increment in a* (-7.017) after 48 hours of storage duration at 10°C. Overall, bruising increased the occurrence of a* value changes, particularly at room temperature. This is attributed to the loss of green color on pears surface [19].

The obtained results showed no pronounce significance (p=0.12570) impact of drop height on b* value of pear. However, storage temperature significantly (p=0.04953) affects the b* value of the bruised pears (Table 2). Bruised pear fruits stored at 10°C showed fewer changes on b* value compared to bruised pears stored at 22°C. Chroma of bruised pears was not significantly affected by all studied factors such as drop height (p=0.83202) and storage temperature (p=0.55508) after 48 hours storage period (Table 2). The same scenario was observed on hue values of bruised pears (Table 2).

|

Quality Parameter |

Temp. (°C) |

Day 0 | After 48 hours | ||

| 20 cm | 40 cm | 60 cm | |||

| a* | 10°C | -7.07 ± 1.30 | -7.07 ± 0.50 | -7.05 ± 1.20 | -7.04 ± 2.00 |

| 22°C | -7.02 ± 1.40 | -7.00± 1.10 | -5.35 ± 2.20 | ||

| b* | 10°C | 34.17 ± 1.80 | 33.86± 0.70 | 33.65 ± 1.7 | 34.11 ± 0.50 |

| 22°C | 33.34 ± 0.90 | 32.92 ± 1.2 | 33.95 ± 1.50 | ||

| Chroma | 10°C | 32.22 ± 0.90 | 34.07 ± 0.70 | 34.31 ± 1.4 | 34.87 ± 0.50 |

| 22°C | 34.64 ± 0.70 | 33.67 ± 1.3 | 34.36 ± 1.40 | ||

| Hue | 10°C | -1.35 ± 0.03 | -1.36 ± 0.01 | -1.36 ± 0.04 | -0.36 ± 0.05 |

| 22°C | -1.36 ± 0.04 | -1.36 ± 0.02 | -1.41 ± 0.06 | ||

| TSS (°Brix) | 10°C | 12.5 ± 1.3 | 14.4 ± 0.80 | 14.30 ± 0.10 | 14.90 ± 0.05 |

| 22°C | 14.4 ± 0.80 | 14.03 ± 1.50 | 15.00 ± 0.10 | ||

| Quality parameters | Statistical tests | Drop height (A) |

Storage Temperature (B) |

AB |

| a* | P- value | 0.04567 | 0.02870 | 0.59328 |

| df | 2 | 1 | 2 | |

| F- value | 4.06959 | 7.23033 | 0.54633 | |

| b* | P- value | 0.12570 | 0.04953 | 0.47585 |

| df | 2 | 1 | 2 | |

| F- value | 2.72333 | 3.93107 | 0.79356 | |

| Chroma | P- value | 0.83202 | 0.55507 | 0.69136 |

| df | 2 | 1 | 2 | |

| F- value | 0.04700 | 0.62022 | 0.38201 | |

| Hue | P- value | 0.21183 | 0.16704 | 0.46918 |

| df | 2 | 1 | 2 | |

| F- value | 1.77757 | 2.16448 | 0.80744 | |

| TSS (°Brix) | P- value | 0.24614 | 0.84150 | 0.91653 |

| df | 2 | 1 | 2 | |

| F- value | 1.49141 | 0.04224 | 0.08969 |

3.3. Effect on TSS

Table 1 presents the values of TSS (mean ± Sd) of pears impacted by an impactor from different drop height levels stored at two temperature conditions for 48 hours of storage period. TSS of pear was not significantly affected (p>0.05) by both storage temperature and drop height after 48 hours storage period (Table 2). However, a great increase of TSS on the bruised pears impacted by an impactor from 60 cm stored at 10°C (14.9 °Brix) and 22°C (15.0 °Brix). Storage at 10°C increased TSS of pears by 15.44%, 14.64%, and 19.44% dropped with an impactor from 20 cm, 40 cm, and 60 cm heights respectively. Storage at 22°C also showed a slow increment of TSS on bruised pears by 15.2%, 12.24%, and 20% of the same impact levels, respectively. It was also reported that the TSS content of bananas was increasing after subjected to mechanical damage due to the starch conservation to total soluble sugars as the fruit start to ripen [31].

3.4. Effect on Weight Loss

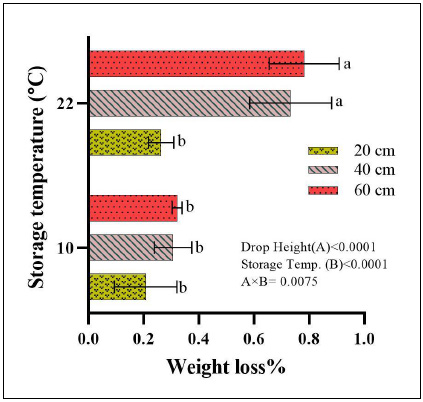

The percentage of weight loss on pear stored at both storage conditions during 48 hours at different impact force levels is shown in Fig. (7). The impact of drop height and temperature condition on the weight loss % of pear fruit was significant (p<0.0001). Weight loss percentage was highly observed on pear bruised with a steel ball from 60 cm and 40 cm drop height compared to the lowest impact (20 cm), particularly at 22°C temperature condition. In the current study, the mean weight loss % of 60 cm bruised pears was varied significantly with the mean weight loss % of other bruised pears at both storage conditions, except for those bruised from 40 cm drop height at 22°C (Fig. 7). After 48 hours storage period, the weight loss percentage increased to reach 0.20%, 0.30%, and 0.32% for 20 cm, 40 cm, and 60 cm drop heights, respectively. Storage at 22°C recorded higher weight loss of 0.24%, 0.73%, and 0.79% for the three impact levels, respectively. The weight loss observed on bruised pears, especially at 22°C could be resulted from permeability modification of cell wall and tissue damage that leads to an increase in the transpiration [32] and respiration rate during storage [33, 34]. A recent study by Hussein et al. [25] also reported that a drop height of 40 cm and 60 cm showed high weight losses of pomegranates at ambient temperature conditions.

3.5. Effect on Firmness

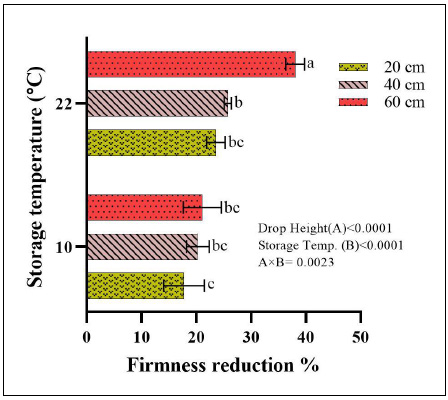

Results of this study showed a significant impact of drop height (p<0.0001) and storage temperature (p<0.0001) on pear surface firmness after 48 hours storage period (Fig. 8). Tukey test results indicated that the mean of firmness reduction % of 60 cm bruised pears stored at room temperature differed significantly from other bruised pears stored at 10 and 22°C storage conditions. Increasing drop height (impact energy) and temperature increased pear firmness reduction for 48 hours storage period. Storage at room temperature and dropping a steel ball from 60 cm reported the greatest reduction in the firmness of pears with 39.87% followed by 40 cm (26.48%) and 20 cm (24.75%) drop hights, respectively. Less firmness reduction was observed on bruised pears stored at 10°C with 17.83%, 20%, and 21.16% after subjected to a steel ball from 20 cm, 40 cm, and 60 cm, respectively. The current study recorded high firmness reduction at ambient temperature which is attributed to the high softening rate of pears stored at this condition [35]. Furthermore, bruising is another factor that can reduce firmness due to increased polygalacturonase activity on pear fruits [36]. Similarly, different studies found that increasing force impact resulted in increasing bruise damage and reducing firmness of pear [2], apple [37], and pomegranate [38]. Cui et al. [30] also confirmed both storage conditions (10°C and room temperature) showed a loss in firmness rate which was highly observed with the increase in drop height level.

CONCLUSION

Mechanical damages like bruising can be affected by many factors like storage temperature and impact level force. Bruise volume and bruise area increased as drop height increased. Furthermore, this study confirmed that impact force of different levels of drop heights (20 cm, 40 cm, and 60 cm) into pears at 22°C and 10°C had significantly increased its susceptibility to bruising, particularly, pears impacted with 60 cm followed by 40 cm and 20 cm drop heights at 22°C. In both storage conditions, L*, a*, weight loss, and firmness were highly affected by drop height. In a short-term study, no significant impact of both temperatures and drop height on the TSS of pears. Therefore, a practical and long-term experiment is required to investigate the relationship between temperature conditions and impact force on bruise susceptibility along with the quality attributes of pear fruits and other local fresh produce.

LIST OF ABBREVIATIONS

| a* | = Redness |

| b* | = Yellowness |

| BA | = Bruise Area |

| BV | = Bruise Volume |

| BS | = Bruise susceptibility |

| L* | = Lightness |

| TSS | = Total Soluble Solids |

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data that support the findings of this study are available from the corresponding author [P. P] upon reasonable request.

FUNDING

This study was supported by Sultan Qaboos University under the project code (IG/AGR/SWAE/19/03) to complete this research work.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

ACKNOWLEDGEMENTS

Declared none.