All published articles of this journal are available on ScienceDirect.

Implications of No-tillage System in Faba Bean Production: Energy Analysis and Potential Agronomic Benefits

Abstract

Background:

Given the nutritional value of faba bean, however its susceptibility to water deficit, especially in Mediterranean environment, tillage practices need to be modified in order to adapt the crop to dry and low rainfall conditions and promote the interest in its cultivation.

Objective:

To identify whether no-tillage system can be considered as a sustainable means in faba bean cultivation under Mediterranean condition.

Method:

The study was conducted during a 6-year period (2010/11 to 2015/16) in southern Italy within wheat-faba bean rotation framework of a long-term experiment. The effect of No-Tillage (NT) on agronomic and energy parameters of faba bean (Vicia faba L.) cultivation was evaluated and compared to those of Conventional (CT) and Reduced (RT) Tillage.

Results:

The agronomic results indicate that NT performed better and/or is comparable to CT, while its application was 28% and 30% more energy efficient compared to CT and RT respectively. For agronomic parameters, tillage had a significant effect on number of plant m-2, grain yield, grain protein content and 100-seed weight whereas year effect was significant for yield components and quality parameters. Energy indexes, instead, were significantly affected by both factors. NT gave the best results in terms of energy efficiency, energy intensity and net energy, and consumed 39% and 36% less non-renewable energy than CT and RT, respectively.

Conclusion:

Our findings revealed that the key benefit of NT in rainfed faba bean is its ability to produce sufficient yield of high quality with a significant reduction in energy inputs entailed the fewest field operations and therefore lowest energy requirements.

1. INTRODUCTION

Grain legumes (e.g. faba bean) are minor crops compared to cereals, but they are important in farming systems, and are used as a source of protein in human diets, as fodder and a forage crop for animals, and as a source of biological nitrogen [1]. Traditionally, faba bean (Vicia faba L.) is grown in southern Italy as a component of rainfed agricultural systems where it is generally grown in rotation with cereals contributing positively to agroecosystem sustainability [2]. Crèpon i.e. [3] indicated that the nutritional value of faba bean is high, and in some areas, this value can be superior to peas or other grain legumes. In fact, faba bean represents a staple food in several parts of the world including Middle East, Mediterranean region, China and Ethiopia adding a socio-economic value to the crop. Nevertheless, the total area sown to faba bean at global level has declined by 56% over the past 50 years [4]. In Italy, dramatic decline in the cultivation area of faba bean was observed over the same period [5] due to its high sensitivity to several kind of abiotic as well as biotic stresses [6, 7] which resulted in yield instability, and therefore lower profitability compared to other cash crops (particularly cereals). It is generally accepted that the lack of moisture limits productivity of rainfed crops, and this is certainly the case for southern Italy, where soils have generally poor moisture holding capacities. In contrast to chickpea (Cicer arietinum L.) and lentil (Lens culinaris L.) as drought tolerance crops, faba bean has a shallow root system and is very sensitive to high temperatures and water stress, particularly during anthesis and pod filling [8], which make it unsuitable for dryland production in Mediterranean-type environments. However, according to ICARDA, faba bean can be considered suitable for production in Mediterranean-type environments with rainfall amount exceeding 400 mm per year. Therefore, agronomical management of the crop should be optimized for yield stability, and to satisfy the growing interest in faba bean cultivation [9] and to promote for wider adoption. In addition, the potential role of faba bean as a source of N for future cropping systems should be reassessed given the limited resources of fossil energy and renewing health and environmental concerns [10]. Reintroducing faba bean into Mediterranean rainfed cropping systems involves several agronomic, environmental [4] and ecological services [10], which goes in line with the need to reduce the negative impact of agriculture on the environment by reducing the fossil energy consumption [4, 5]. In today’s agricultural practices, soil tillage and applications of chemicals are the greatest consumers of energy and labor. Since fertilization is lowered to the minimum due to N2 fixation from faba bean, the selection of an appropriate tillage method will lead to an improvement of energy use efficiency, reduce the input costs [11] and increase cop profitability, and therefore system sustainability [12]. The application of no tillage practice [13] in order to adapt the crop to dry and low rainfall conditions while reducing the reliance on fossil fuel has been tested and described as potentially advantageous adaptations of faba bean to rainfed cultivation in drylands. In Mediterranean area, conservation tillage techniques e.g. no-tillage system are becoming increasingly popular due to their potential to generate environmental, agronomic [14] and economic benefit [15] compared to traditional tillage methods. Despite the yield advantage of no tillage system due to water conservation, especially in rainfed crop, the role of this technique in faba bean production with reference to energy consumption is not well investigated in Mediterranean area, especially in southern Italy. Previous studies have studied the effect of no tillage on faba bean productivity [15, 16] and/or assessment of N losses via soil biological processes [5]. According to the authors’ knowledge, studies to evaluate the effect of no-tillage use on the agronomic performance of faba bean, particularly in Mediterranean regions, with reference to energy consumption are absent in the per-reviewed literature. Hence, given the nutritional value and the socio-economic importance of faba bean for the Mediterranean area, it was important in this study to focus on potential improvement of energy use efficiency in faba bean production in southern Italy without affecting yield. Due to the increasing demand by consumers and governments to reduce the negative impacts of agricultural activities on the environment through new and more sustainable approaches to food production, we aimed at investigating the possibility to reduce crop energy requirements for optimal faba bean production. The objective of this study is to identify alternative tillage practices for sustainable faba bean production in the dry area of southern Italy.

2. MATERIALS AND METHODS

2.1. Study Area

The data used in this study were collected directly from field experiments conducted at the experimental farm “E. Pantanelli”, University of Bari, in a typical Mediterranean area (southern Italy), located in Policoro ((MT); 40°10’20” N, 16°39’04” E). The experimental site is 15 m above sea level and is characterized by sub-arid climate according to De Martonne classification [17]. The temperature is a typical of Mediterranean climate with a maximum temperature reaching 40-42°C in the summer. The average annual rainfall is about 560 mm distributed mainly during autumn and winter. The surface soil texture is loamy (sand, 39.78%; silt, 37.40%; clay, 22.28%) according to USDA classification system. Furthermore, based on the analysis of soil at the study site before the start of the experiment, the following soil characteristics were therefore reported; total nitrogen (Kjeldahl method) = 0.196 %, P2O2 (Olsen Method) = 40 ppm, Nitrate =14.3 ppm, organic matter (Walkley-Black method) = 2.8%, total lime = 8.8% and PH = 7.72.

2.2. Experimental Design

Field experiment was established within a long-term rotation experiment started in 2009 to test the ability of conservation tillage technique (no-tillage system) to sustain/improve the agronomic and environmental performances of faba bean in a key legume cultivation area in southern Italy. In this regard, we study the response of faba bean yield and quality parameters to different tillage systems in the dry area. The effect of No-Tillage (NT) system on energy balance was also evaluated and compared to Reduced (RT) and Conventional (CT) Tillage systems over a 6-year period (2010/11 to 2015/16 growing season). The investigated growing seasons are referred to hereinafter as 2011, 2012, 2013, 2014, 2015 and 2016. Faba bean (Vicia faba var. equina Pers.) cv PROTHABAT 69 was grown in rotation with durum wheat (Triticum turgidum L.var. durum) cv IRIDE under rainfed condition. Both faba bean and wheat experimental fields were arranged in a split-plot design with three replicates.

2.3. Crop Management

Agricultural practices for the faba bean field included soil preparation, seeding, fertilization, herbicide application and harvesting. All practices applied for faba bean production in this study are listed in Table 1. Essential soil disturbance and seedbed preparation were performed in RT and CT before sowing, while faba bean was sown in an unprepared soil. Every year, faba bean crop was sown in November and harvested at maturity in June. Sowing was affected using different sowing machines by opening a narrow slot. In NT system, sowing the crop in undisturbed soil was affected using sod-seeder (IGEA 2700 SEMINASODO) to obtain the proper seed coverage without soil preparation, while in RT and CT system conventional seed driller (LAROCCA 14 FALC) was used. Faba bean (Vicia faba var. equina Pers.) cv PROTHABAT 69 was sown at the rate of 180 kg ha-1 in the three tillage systems. The crop was planted at row spacing of 35 cm in order to obtain 55 seeds m-2. The faba bean field received no N fertilizer, while phosphorus fertilizer was applied as simple superphosphate (200 kg ha−1) at dose of 40 kg ha−1 P2O5 to all plots prior to sowing, every year. For weed control, glyphosate [N-(phosphonomethyl)-glycine] was sprayed before sowing in NT system, whereas ALTOREX and Fusilade DX were topdress applied in the three tillage systems (Table 1).

| Practice/operation | Tractor | CT | RT | NT | Timing | Diesel fuel (L) | Machine Description | Additional information |

|---|---|---|---|---|---|---|---|---|

| Subsoiler at 30 cm | JHON DEERE 4RM (380 Kw) | na | √ | na | August | 50 | Chisel (VOLGARINO) 7 | Soil preparation |

| Mouldboard at 35 cm | JHON DEERE 4RM (240 Kw) | √ | na | na | August | 60 | Multi-furrow plough (KHUN) 35 cm | Soil preparation |

| Disc Harrowing at 15 cm | FIAT LINBOLO (60 Kw) | √ | √ | na | November | 40 | Disc harrow 22 (NARDI) 15 cm | Seedbed preparation |

| Sowing | FIAT-50 4RM (50 Kw) | √ | √ | na | November | 10 | Seed driller (LAROCCA 14 FALC) | Fava bean seeds (cultivar 'Prothabat 69') at a rate of 180 kg ha-1 |

| Sowing | JHON DEERE 4RM (240 Kw) | na | na | √ | November | 20 | Sod-seeder (LA SIMINASODO IGEA 2700) | Fava bean seeds (cultivar 'Prothabat 69') at a rate of 180 kg ha-1 |

| Fertilizer application | FIAT-50 4RM (50 Kw) | √ | √ | √ | October | 7 | Spinning fertilizer distributer (OMA 400) | Single superphosphate (SSP) 200 kg ha-1 |

| Herbicide application | FIAT-50 4RM (50 Kw) | √ | √ | √ | March | 7 | Crop sprayer | ALTOREX (1 l ha-1) + Fusilade DX (1,5 l ha-1) |

| Herbicide application before sowing | FIAT-50 4RM (50 Kw) | na | na | √ | September | 7 | Crop sprayer | Glyphosate (1,5 l ha-1) + sulphate ammonium (800 g ha-1) |

| Harvesting | JHON DEERE 2RM (380 Kw) | √ | √ | √ | June | 20 | Combine harvester T660-I L.B 850 m |

2.4. Data Collection and Analysis

Biological yield data were collected directly from the experimental site every year. A plot combine harvester (WINTERSTEIGER classic - 1.4 m wide) was used to harvest the crop. Biological yield and grain yield were measured at harvesting and recorded for each plot, every year. The data was then used to calculate the harvesting index for each plot. Given the size of each plot (2450 m-2), biological yield data were taken as the average of three harvesting time, following a linear pattern of 20 m in length, around the center of each plot. In addition, the number of plants in one linear meter was measured before harvesting as an important morphological parameter that reflects the growth status of the crop. Each year, after harvesting, grain yield samples were transported to the lab for quality determination. The following quality parameters were therefore determined; 100-seed weight (g), hectoliter weight (Kg hl-1), humidity (%), grain protein content (%) in each plot, each year. Test weight and grain humidity were measured using (Agricultural Tester Aquasearch 600), while protein content was determined using the NIR FOSS Infratec 1241-grain analyzer, which measures the protein content in whole grain at a European standard. Data, for each parameter and each treatment, are reported as the average of six growing seasons (2010/11–2015/16) and three replicates. For energy analysis, the study has considered only the energy used in faba bean production, without taking into account the environmental source of energy (radiation, rain, etc.). Human labor, machinery, diesel fuel, chemical fertilizers, herbicides and seed amounts and output yield values of faba bean crop have been used to investigate the energy pattern.

2.5. Energy Analysis

The energy equivalents of different inputs and the outputs in faba bean production are shown in Table 2. Due to the lack of study to calculate the energy equivalents (MJ/unit) for different input parameters (human labor, fertilizer, herbicide, diesel fuel, seeds and farm machinery) and the output (grain and straw yield) in Italy, these coefficients were obtained from different studies in the literature (Table 2). Based on energy equivalents for the different inputs and the output with their quantities collected from the field experiments (Table 1), energy inputs (both direct and indirect) and the energy output were evaluated using existing formulas [18]. Energy input was calculated using the energy equivalent of different inputs. The total input energy was the sum of all components of energy used in the production of the output. Both direct and indirect energy inputs were calculated as the sum of biological energy (human labor, seed), chemical energy (fertilizer, herbicide), and field operational energy (see, Alhajj Ali i.e. [18]). In details, direct energy consists of diesel fuel consumption and human labor while indirect energy comprises the energy used for machinery, fertilizer, herbicide and seed [19]. Total energy output in faba bean is usually calculated based on the main product (energy faba bean grain). However, in order to complete the energy balance in faba bean production, it was essential to consider the output energy for the byproduct source, i.e. the amount of energy stored in faba bean straw due to its economic [20] and environmental values. According to the authors' knowledge, the amount of energy (MJ Kg-1) in faba bean straw was not reported in peer-reviewed literature. Therefore, we have estimated the amount of energy in faba bean straw in terms of gross energy [21], which is determined by oxidizing (burning) the feedstuff and measuring the energy released as heat [22]. Gross energy content in faba bean straw grown in Mediterranean region was taken from Feedipedia [23] and Hadjipanayiotou i.e. [24] and used to estimate average energy equivalent value (Table 2). Total energy output was then calculated as described by Taner i.e. [19] using the following Eq (1):

|

(1) |

Where, EO is the energy output (MJ ha−1), Eg is the energy output from grain (MJ ha−1) and Es is the energy output from straw (MJ ha−1).

| Particulars | Unit |

Energy Equivalent (MJ unit−1) |

Reference | Remarks |

|---|---|---|---|---|

| A. Inputs | ||||

| 1. Human labor | h | 1.96 | [12, 52, 53] | Human Male (1.78 MJ as direct and 0.18 MJ as indirect) |

| 2. Machinery | h | 62.70 | [54, 55] | Distributing the energy used in manufacture over the lifetime of the machinery |

| 3. Diesel fuel | L | 56.31 | [18, 54, 56] | The production of one liter of petroleum-derived diesel Including lubricant |

| 4. Phosphorus (P2O5) fertilizer | kg | 12.44 | [26, 52] | Energy required for manufacture of kg P2O5 as fertilizer |

| 5. Herbicide | L | 238.00 | [47, 54] | Energy required for manufacture of 1 liter of herbicide; Requires dilution at the time of application |

| 6. Seeds (faba bean) | kg | 21.00 | [47] | Dry weight as an output of crop production system |

| B. Outputs | ||||

| 1. Dry grain | kg | 20.00 | [12, 47] | Gross energy in faba bean grain (dry weight) |

| 2. Faba bean straw | kg | 17.65 | - | Calculated value from Feedipedia [23] and Hadjipanayiotou et al. [24] based on the amount of energy released as heat (gross energy) in faba bean straw (dry matter) |

Following the calculation of energy inputs and outputs, energy use efficiency, energy production, energy intensity, net energy, energy profitability and human energy profitability were calculated for faba bean production by the following Eqs. (2-5 from Hamzei and Seyyedi [11] while Eq: 6-7 from Tabatabaeefar i.e. [25]):

|

(2) |

|

(3) |

|

(4) |

|

(5) |

|

(6) |

|

(7) |

In the light of energy use calculation, renewable and non-renewable energy were evaluate to assess the sustainability of the system. Renewable energy consists of energy from human labor and faba bean seeds, whereas non-renewable energy was calculated as the sum of total energy from diesel fuel, fertilizers, herbicide and machinery [26-28].

2.6. Statistical Analysis

Annual data for both energy and agronomic parameters over the whole 6-year period were subjected to Analysis Of Variance (ANOVA) in which the year (n=6) was considered as a repeated variable, while the factor of interest (tillage system) was considered to be fixed. Comparison of the means was made using the Least Significant Difference (LSD) test at P ≤ 0.05 probability level with CoStat software.

3. RESULTS AND DISCUSSION

3.1. Weather

Total seasonal and monthly rainfall distribution, as well as the average temperatures during faba bean growing season, are shown in Table 3. Both total rainfall amount and monthly distribution varied markedly from year to year during the experimental period (November-June). In the 6-year, rainfall was largely confined to the November to May period (Table 3), and it is likely that little moisture was stored in the soil from rainfall outside this period (i.e. October). The growing season 2013/14 was particularly wet (> 600 mm of total rainfall) while other five seasons reported an average rainfall of about 400 mm (Table 3), with the last season (2015/16) being the driest (374.4 mm). Table 3 shows the variability of average temperatures during October-June period for the six growing season. The analysis of mean growing season average temperature indicate that the first three growing season (2011-13) were the hottest (average temperature ranged between 14.9°C and 14.5°C) whereas the last three seasons (2014 to 2016) reported lower temperature (ranged between 13.9°C and 14.3°C). The analysis of individual growing season indicate that the hottest season was the first season (2011, 14.9°C) with the highest temperature reported between May-June, while the 2015 season was relatively cold (13.9°C) with the highest temperature reported in June (20°C) (Table 3).

| Crop cycle (Month) | 2010/11 | 2011/12 | 2012/13 | 2013/14 | 2014/15 | 2015/16 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rain (mm) |

TAve. (°C) |

Rain (mm) |

TAve. (°C) |

Rain (mm) |

TAve. (°C) |

Rain (mm) |

TAve. (°C) |

Rain (mm) |

TAve. (°C) |

Rain (mm) |

TAve. (°C) |

|

| October | 109.2 | 17.5 | 11.4 | 18.6 | 8.1 | 19.1 | 97.2 | 18.1 | 39.7 | 18.3 | 13.1 | 18.2 |

| November | 51.8 | 15.6 | 63 | 15.6 | 77.3 | 14.4 | 165.6 | 13.3 | 72.9 | 15.2 | 24.5 | 19.3 |

| December | 7.8 | 10.6 | 53.1 | 11.3 | 79.3 | 11.5 | 192.1 | 9.7 | 22.9 | 10.5 | 0 | 7.7 |

| January | 71.6 | 8.8 | 67.1 | 9.0 | 67.7 | 9.1 | 41.5 | 9.6 | 32 | 9.2 | 7.6 | 9.6 |

| February | 59.4 | 10.1 | 112 | 8.9 | 48.8 | 9.5 | 76.7 | 11.6 | 113 | 8.7 | 31.1 | 11.0 |

| March | 123.7 | 12.0 | 12.4 | 12.6 | 55.4 | 11.3 | 54.6 | 11.5 | 110.7 | 11.1 | 214.2 | 10.5 |

| April | 58.5 | 15.7 | 56.9 | 13.4 | 34.5 | 14.8 | 105.3 | 14.0 | 10 | 13.6 | 3 | 13.7 |

| May | 26.1 | 19.3 | 22.7 | 17.8 | 29.3 | 18.3 | 30.7 | 16.5 | 12.8 | 18.0 | 65.5 | 15.8 |

| June | 20 | 24.3 | 6.1 | 24.1 | 17.9 | 22.7 | 44 | 22.5 | 44.4 | 20.0 | 28.5 | 22.5 |

| Sum | 418.8 | - | 393.3 | - | 410.2 | - | 612.8 | - | 418.3 | - | 374.4 | - |

| Mean | - | 14.9 | - | 14.6 | - | 14.5 | - | 14.1 | - | 13.9 | - | 14.3 |

3.2. Faba Bean Grain Yield and Yield Components

Effects of tillage system and the study year on faba bean yield, yield components and quality traits are reported in Table 4. Average data, for all the parameters, showed a high variability between tillage systems and the study years, due to various factors including climate (i.e. precipitation, temperature and water stress) and technical variables (i.e. sowing date, weed infestation and crop lodging) (data not published). Toker [29] found that the biological yield of faba bean was strongly affected by environmental conditions, whereas Ruisi et al. [5] investigated 25-year average data of faba bean production in southern Italy and found much higher variability this crop than in other crops due to it high sensitivity to abiotic and biotic stress. The statistical analysis indicate that tillage effect was highly significant (P ≤ 0.001) on the number of plant m-2, on the grain yield (P ≤ 0.01) and less significant (P ≤ 0.05) on the 100-seeds weight and grain protein content, whereas tillage effect showed no significant effect on other investigated parameters (Table 4). Year effect, instead, showed highly significant (P ≤ 0.001) effect on all parameters indicating the importance of inter-annual variation of rainfall and temperatures during the growing season especially in the rainfed areas. The interaction effect (Tillage × Year) was also significant except for hectoliter weight data.

| Treatment | N° plant m-2 |

Yield (kg ha-1) |

Straw (kg ha-1) |

HI (%) | Humidity (%) | Hectoliter Weight (kg/hl) |

100-Seed Weight (g) |

Protein (%) |

|---|---|---|---|---|---|---|---|---|

| Tillage | *** | ** | ns | ns | ns | ns | * | * |

| Conventional (CT) | 30 a | 3029.7 a | 5702.5 | 0.35 | 8.4 | 79.5 | 55.2 a | 25.8 a |

| Reduced (RT) | 31 a | 2768.4 b | 5424.9 | 0.34 | 8.4 | 79.4 | 53.8 b | 25.4 b |

| No-Tillage (NT) | 26 b | 2986.6 a | 5584.7 | 0.35 | 8.5 | 79.6 | 53.6 b | 25.8 a |

| Year | *** | *** | *** | *** | *** | *** | *** | *** |

| 2011 | 28 c | 1332.8 e | 2542.1 d | 0.34 c | 9.7 a | 77.3 c | 49.4 d | 23.8 c |

| 2012 | 33 a | 2476.9 d | 5027.8 c | 0.33 c | 6.7 f | 79.4 b | 46.5 e | 27.5 a |

| 2013 | 29 bc | 3047.4 c | 4930.6 c | 0.38 b | 8.4 d | 79.1 b | 50.0 d | 26.1 b |

| 2014 | 30 b | 3474.6 b | 8866.7 a | 0.28 d | 7.6 e | 78.8 b | 68.4 a | 27.5 a |

| 2015 | 34 a | 4583.9 a | 5223.5 c | 0.47 a | 9.4 b | 81.6 a | 53.3 c | 23.5 c |

| 2016 | 22 d | 2653.8 d | 6833.3 b | 0.28 d | 9.1 c | 81.0 a | 57.7 b | 25.8 b |

| Mean | 29.2 | 2928.2 | 5570.7 | 0.35 | 8.4 | 79.5 | 54.2 | 25.7 |

| Interaction | ||||||||

| Year x Tillage | *** | *** | *** | *** | *** | ns | ** | ** |

3.2.1. Grain Yield

Productive data showed that the machine-harvested seed yields were much lower (1332.8 kg ha-1) in the first year (2011) compared to the other five years due to lodging effect (data not present) while reached its peak in 2015 (4583.9 kg ha-1), and thereafter faba bean grain yields resulted in a significant decline (42%) in the last year (Table 4). In fact, yield instability is famous in this crop [5, 30]); however, average yield that characterizes faba bean in this study (2928.2 kg ha-1 (2.9 t ha-1)) is significantly higher than the regional (1.8 t ha-1) and the national average (1.9 t ha-1) reported by ISTAT, and the world average (1.7 t ha-1) reported by FAOSTAT. According to Loss and Siddique [8], faba bean is able to produce sufficient biomass and seed yield in a range of dry land Mediterranean-type environments. Under the same field conditions, our yield average was within the range measured by Ruisi i.e. [31] (1.7–4.0 t ha−1) across four years and two tillage systems (CT vs. NT) for faba bean production in Southern Italy. Similarly, Giambalvo i.e. [15] reported an average yield of 2.02 t ha-1 for faba bean production in Sicily, southern Italy. Recent work by Volpi i.e. [32] reported close value (3.2 t ha-1) for V. faba production in central Italy. Regarding tillage effect, the analysis of variance showed significant (P ≤ 0.01) influence on faba bean grain yield (Table 4). Significantly higher yield was obtained under NT than RT, however slightly lower but comparable to grain yield under CT. On average, CT resulted in higher grain yield (3029.7 Kg ha-1) followed by NT (2986.6 Kg ha-1) whereas RT reported the lowest yield with 2768.4 Kg ha-1. The analysis of yield results, for each individual year, indicate that yield advantage of NT over CT and RT was more pronounced in the first three years (2011 to 2013) under low rainfall amount but good rainfall distribution, in contrast to the last three years (2014 to 2016) when CT resulted in some yield advantages over NT. Being the hottest seasons (2011 to 2013), with average seasonal temperature ranged between 14.9°C to 14.5°C, we believe that the interaction between high temperature and low rainfall favored yield response under no-tillage in these seasons due to its ability to hold water. In contrast to the last three seasons (2014 to 2016) with higher rainfall and lower temperature (ranged between 13.9°C and 14.3°C) that favored yield response to CT over NT. In fact, the inter-annual variation was confirmed by the highly significant interactions between year and tillage (Table 4). Under rainfed Mediterranean conditions, several studies (e.g. Giambalvo i.e. [15]) have reported that yield response to NT over CT was linked to the dry seasons. Ruisi i.e. [31], for example, have concluded that the application of NT system has led to an improvement in faba bean productivity in southern Italy, particularly under conditions of deficient soil moisture. In southern Spain, Fernández et al. [33] reported a large yield increase in legume plants under NT compared to CT in the dry years of a 21-year experiment. Comparing our results with the previous ones conducted in the same environment, we found that yield performance under NT was not surprising due to its ability to reduce soil water evaporation from the presence of crop residues on the soil surface [34] and the increase in infiltration rates due to more stable structure, which therefore have led to greater soil water storage under NT than CT [35]. Another reason could be attributed to the favorable development of the faba bean root system under NT under Mediterranean climate as reported by Muñoz-Romero i.e. [36]. In the present study, year effect had clear influence on grain yield and varied significantly from a minimum of 1332.8 Kg ha-1 in the first year (2011) to a maximum of 4583.9 Kg ha-1 reported in 2015 (Table 4). The high variability of grain yield across the study years was due to many factors including rainfall amount and distribution, temperature and photoperiod [37].

3.2.2. Straw Yield

Due to the economic value of faba bean straw as a cash crop in some Mediterranean countries [20], and as a biomass to produce bioethanol and biogas in some European countries [38], special attention was given in this study to the efficiency of straw production following the principles of conservation agriculture (i.e. NT system). This help to understand whether the conservation farming technique is an alternative practice to the conventional one in terms of energy production. Alluvione i.e. [21] stated that, if harvested, straw yield can double the energy output of the crop. Being left on the soil surface i.e. in NT system, the total energy in crop straw and/or residues carry a very high ecological importance as they provide the energy support for the meso- and micro-organisms that live in the fields and feed on them [39, 40]. At the end of the study years, average of 5570.7 Kg ha-1 of harvested faba bean straw (stems + leaves + hulled pods) was reported and varied significantly across years (Table 4). Despite the slight differences in faba bean straw yield, tillage system showed no significant effect on this parameter, in agreement with Giambalvo et al. [15] who found no differences among NT, RT, and CT in terms of straw production over 18 years of faba bean production in southern Italy. In contrast, Muñoz-Romero i.e. [36] found significant higher faba bean (Vicia faba L.) straw yield under NT than under CT in southern Spain due to the more favorable condition for the development of the faba bean root system. For year effect, Giambalvo i.e. [15] found significant variation in straw yield (from 0.78 to 5.11 t ha−1) across the study years, in agreement with the present study. Year effect was highly significant (P≤0.001) with the highest average (8866.7 Kg ha-1) being reported in 2014 and the lowest in the first year (2011) with only 2542.1 Kg ha-1 (Table 4). The analysis of the results showed no positive correlation between straw and grain yields in all the years. This was the result of seasonal rainfall amount and/or distribution, which in some years stimulate the vegetative production over grain yield. This was the case in 2014 season where significant higher amount of rainfall (Table 3) stimulated plant growth and resulted in significant higher straw yield compared to grain yield and therefore significant lower harvest index. Our findings were in agreement with the previous study by Sau and Mínguez [41] for faba bean adoption in Mediterranean climate. The authors indicate that greater biomass production was not associated with greater yield, because of low mobilization (reflected by a decrease in harvest index).

3.2.3. Harvest Index

Previous studies stated that harvest index of legumes crop is usually overestimated; therefore, care must be taken when comparing the harvest indexes of crops because, unlike cereals, faba bean leaves, for example, are shed during senescence, leaving mainly stems and pods at maturity [8]. On average, the harvest index for faba bean crop calculated to be 0.35 (Table 4). Significant variation were reported in harvest index between the study years (Table 4). This variation reported to be the highest in 2015 (0.47) and lowest in 2014 and 2016 with 0.28. This high variability in harvest index across the years was previously reported by other authors for other grain legumes such as chickpeas [42] and lupin [43]. The decrease in harvest index and the high variability reflects the fact that there is no positive correlation between grain and straw yield. This confirm the fact that this index is highly influenced by the total aboveground biomass, and not by the single yield component (yield or straw). Tillage system had no significant effect on harvest index, whereas the interaction (Year x Tillage) was highly significant reflecting the ability of tillage system to influence plant growth and development over time due to the enhancement of soil conditions.

3.3. Faba Bean Grain Quality

Quality traits (hectoliter weight, 1000-seed weight, humidity and grain protein content) were investigated in this study. Their variation under different tillage systems and across the study years are present in Table 4. The table showed that tillage effect was significant (P≤0.05) on 1000-seed weight and grain protein content, whereas year effect showed high significance (P≤0.001) on all quality traits. The interaction effect (Year x Tillage) was significant except for hectoliter weight. Despite higher values under NT system, no significant differences were observed among NT, RT, and CT for both humidity and hectoliter weight. Average data showed that the highest 1000-seed weight (55.2 g) was reported in CT, significantly higher than RT (53.8) and NT (53.6), in contrast to the findings of Giambalvo i.e. [15] who found no differences among NT, RT, and CT for 100-seed weight in faba bean production in southern Italy. For grain protein content, NT give higher value (25.8%) comparable to the one of CT and significantly higher than grain protein content reported under RT (25.4%). Higher variability were reported across years for all quality traits (Table 4). Best results were recorded in 2014 and 2015 growing season presumably due to the relative low temperature and higher rainfall amount comparing to other growing seasons. In particular, highest values for humidity and hectoliter weight were recorder in 2015 with highest grain yield (their values were 9.4% and 81.6 kg hl-1 respectively), while 1000-seed weight and grain protein content were recorder in 2014 with the highest straw yield (their values were 68.4 g and 27.5% respectively). The data somehow indicate revere relationship between grain yield and grain protein content through immobilization and dilution effect, although this relationship was not observed across the years due to interaction effect between soil management, temperature and rainfall amount and distribution. The revere relationship, however, was observed when significantly lower protein content (23.5%) was reported in 2015 where the highest grain yield was obtained.

3.4. Energy Analysis

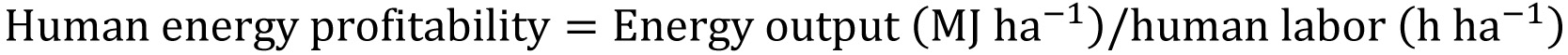

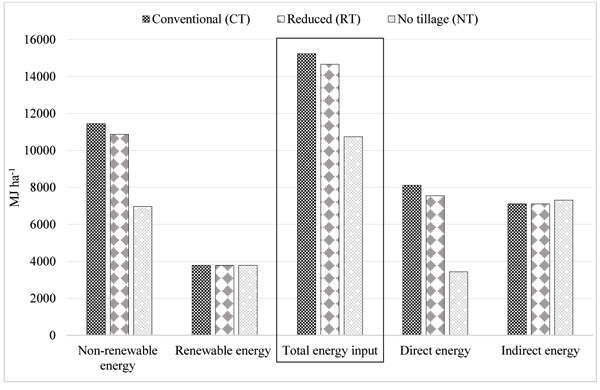

The analysis of the overall results indicate that the total energy input consumed in faba bean production was classified as direct energy (46%) and indirect energy (54%), and renewable energy (29%) and non-renewable energy (71%) (Fig. 1). The figure shows that NT system used higher renewable energy (+35%) compared to CT and RT, indicating high potential of system sustainability. Fig. (2) illustrates the amount (MJ/ha) of different energy classification (renewable energy vs. non-renewable energy) and (direct energy vs. indirect energy) to the total energy input under the three tillage systems. Energy equivalent share (%) of different input source to the total energy input in faba bean production are shown in Fig. (3) for the three tillage systems. The analysis of the results indicate that NT system required lower energy input due to fewest field operations and therefore lowest energy requirements, in agreement with Rathke i.e. [44] for soybean production eastern Nebraska. In fact, the implementation of NT system in this study reduced the consumption of total energy input by 29% compared to RT and CT; most of this energy (32%) were generated from diesel fuel consumption in tillage operations (Fig. 3). It has previously been reported that the energy input of diesel fuel has the biggest share of the total energy input in agricultural crops production [18]. The study of Rathke i.e. [44] found that fuel consumption had the biggest share to the total energy input in soybean production systems, because no fertilizer was applied to the soybean crop. In this study, the phosphorus (P2O5) fertilizer-related energy share (18.8%) ranked the third contributor after diesel fuel (45.6%) and faba bean seeds (28.6%) due to lower energy equivalent coefficient of phosphorus fertilizer compared to nitrogen (N) fertilizers (12.44 vs. 78.23 MJ Kg-1). Several studies reported much higher fertilizer-related energy and being the largest contributor to the total energy input due to the application of N fertilizers.

3.4.1. Input/Output Analysis

Total energy input consumed in faba bean production was classified as direct energy (46%), indirect energy (54%), renewable energy (29%) and non-renewable energy (71%). Among the input parameters, diesel fuel (45.6%), seed (28.6%), and phosphorus (18.8%) were the major contributors to the total energy use in faba bean under rainfed condition. Total energy output was very much linked the biological yield. The highest energy producer system depended therefore on its ability to produce higher grain and straw yield. The energy input/output analysis indicate that, on average, our faba bean production system has used a total energy input of 13544.6 MJ ha-1 to produce 156887.1 MJ ha-1 of output energy. Despite the use of the same quantity of energy input every year, the effect of tillage system was significant with the highest energy input being used in CT (15229.2 MJ ha-1) and the lowest in NT (10745 MJ ha-1). Our average energy input value was in line with the one (13833.7 MJ ha-1) reported by Kazemi et al. [12] for faba bean production across 30 farms in Golestan province of Iran. Their energy output, however, were about 50% less than the average value reported in this study. Another study by Ramedani i.e. [28] reported close energy input value (18026.5 MJ ha-1) for soybean production in Kordkuy county of Iran, whereas their average energy output (71228.9 MJ ha-1) was much lower compared to the one reported in this study. According to the authors’ knowledge, the amount of energy stored in faba bean straw has not been included in peer-reviewed study regarding the energy analysis in faba bean production. Since straw was harvested in this study, much higher energy output is expected compared to those reported in the literature due to the inclusion of output energy from the byproduct source. It has been stated that the total energy output is nearly doubled when straw is harvested since grain and straw have similar gross energy contents [45]. In this study, the analysis of data showed that energy output values varied significantly across tillage systems and the study years (Fig. 4). On average, the total energy output was always higher than energy input and reported to be 10 times higher than energy input at the end of the study years indicating the sustainability of the system. The average data showed that CT system produced higher energy output (161242.2 MJ ha-1) significantly higher than NT and RT with 158301.6 MJ ha-1 and 151117.5 MJ ha-1 respectively (Fig. 4). Total energy output as affected by the study years showed high variability and very much depended on the production of biological yield. For example, the highest output energy (225988.4 MJ ha-1) was reported in 2014 (68% higher compared to the first year) when significant higher straw yield was produced and the second highest output energy (182873.5 MJ ha-1) was reported in 2015 where significant higher grain yield was obtained (Table 4). Similarly, much lower output energy (71525.3 MJ ha-1) was reported when significant reduction of grain and straw yield was reported in 2011 (Table 4).

3.4.2. Energy Indexes

The energy use efficiency (energy ratio), energy production, energy intensity, net energy, energy profitability and human energy profitability in faba bean production were calculated and shown in Table 5. The effects of both tillage systems and the study years were significant for all energy indexes. The analysis of the results showed that NT system was the best-performed scenario while RT was the worst scenario for all energy indexes (Table 5). As most of energy indexes are strongly influenced by energy balance (input/output), year effect followed the same trend of energy output. The best values were obtained in 2014 for energy use efficiency, net energy, energy profitability and human energy profitability, and in 2015 for energy production and energy intensity. The worst values, instead, were obtained in the first year for all energy indexes (Table 5). In the following is a detailed analysis for each index.

| Treatment | Energy Use Efficiency (MJ ha-1) |

Energy Production (Kg MJ-1) |

Energy Intensity (MJ kg-1) |

Net Energy (MJ ha-1) |

Energy Profitability (MJ ha-1) |

Human Energy Profitability (MJ h-1) |

|---|---|---|---|---|---|---|

| Tillage | *** | *** | *** | * | *** | *** |

| Conventional (CT) | 10.6 b | 0.199 b | 6.5 a | 146013 a | 9.6 b | 23852.4 b |

| Reduced (RT) | 10.3 b | 0.189 b | 6.4 a | 136457.8 b | 9.3 b | 22927.8 b |

| No-Tillage (NT) | 14.7 a | 0.278 a | 4.1 b | 147556.6 a | 13.7 a | 66906.8 a |

| Year | *** | *** | *** | *** | *** | *** |

| 2011 | 5.5 e | 0.103 e | 11.2 a | 57980.6 d | 4.5 e | 17819.2 e |

| 2012 | 10.5 d | 0.188 d | 5.5 b | 124734.1 c | 9.5 d | 33823.5 d |

| 2013 | 11.4 c | 0.234 c | 4.6 bc | 134427.8 c | 10.4 c | 38114.7 c |

| 2014 | 16.9 a | 0.260 b | 3.9 cd | 212443.7 a | 15.9 a | 52153.5 a |

| 2015 | 13.9 b | 0.346 a | 2.9 d | 170328.9 b | 12.9 b | 43831.1 b |

| 2016 | 13.1 b | 0.200 d | 5.7 b | 160139.6 b | 12.1 b | 41632.2 b |

| Mean | 11.9 | 0.222 | 5.6 | 143342.5 | 10.9 | 37895.7 |

| Interaction | ||||||

| Year x Tillage | *** | *** | *** | *** | *** | *** |

3.4.2.1. Energy Use Efficiency

Energy use efficiency (energy ratio) is considered as indicator to biological yield productivity of the crop, therefore its value is highly influenced by the biological yield (associated energy in it) and the input energy. It has previously been reported that energy efficiency declines with increasing energy input [46]. It has been stated that the efficient use of energy is one of the principal requirements for sustainable agriculture [47]. Therefore, we calculated energy use efficiency under different tillage systems in order to identify the most sustainable one in faba bean production. Any value of energy use efficiency less than one means more energy was consumed than it was produced in terms of output energy, which consider unsustainable [48]. In this study, faba bean crop has average energy use efficiency of 11.9 MJ ha-1 indicate that faba bean production in southern Italy is efficient in the use of energy. This average value varied significantly among tillage systems and across the study years (Table 5). The NT system was 30% and 28% more energy efficient than RT and CT system respectively. Rathke i.e. [44] indicate that the energy use efficiency increases when soil tillage operations were reduced. In this study, the reduction of tillage operations and the associated reduction of labor lead to an increase in energy use efficiency in NT system. Kazemi i.e. [12] indicate that the highest energy use efficiency (energy ratio) can be achieved in those systems having only human effort without fossil fuel input. Taner i.e. [19] found that NT practice had the most appropriate energy use efficiency for dry lands of the central Anatolia region of Turkey. Year effect showed 50-60% higher energy use efficiency in the last years (2014 to 2016) compared to the first year.

3.4.2.2. Energy Production

On average, 0.222 Kg MJ-1 was reported and varied significantly across years and among tillage systems (Table 5). Close average value (0.23 Kg MJ-1) was reported by Kazemi i.e. [12] for faba bean production in northeast of Iran. We found energy production values to follow the same path of energy use efficiency. Zentner i.e. [49] previously observed similar trend. Under year effect, there was an exception where energy production value was the highest (0.346 Kg MJ-1) in 2015 (the highest energy use efficiency was reported in 2014), owing to the greatest harvest index. The lowest production year (had the lowest grain yield value) resulted in a significant reduction (-70%) of energy production compared to 2015. Despite the reduction (-42%) in energy production in the last year compared to 2015, we reported an energy production increase of 48% in the last year compared to the first year. Tillage affect significantly the energy production values indicating an advantage in the use of NT system over CT and RT. This advantage corresponds to an increase in the energy production by 28% and by 32% compared to CT and RT respectively. These results revealed that the RT system is not recommended in rainfed faba bean production due to its lower energy production.

3.4.2.3. Energy Intensity

It referees to the amount of energy required for the production of one kilogram of grain. Low values (close to one) indicate less energy-intense system which was the NT system in our case. In general, energy intensity values followed the same trend of energy production (Table 5), however with reverse relationship (higher energy production corresponds to lower energy intensity). We reported an average value of energy intensity to be 5.6 MJ Kg-1. Kazemi i.e. [12] reported close value (4.25 MJ Kg-1) for faba bean production across 30 farms in Golestan province of Iran. The overall results indicate that energy intensity increased with the increase in management intensity, which was greatly affected by grain productivity [12]. This was clear as significant lower energy intensity value (2.9 MJ Kg-1) was reported when the highest grain yield was reported in 2015, 74% less intense compared to the first year (2011) that produced the lowest grain yield. The effect of tillage system was significant. The NT system was 38% and 36% less energy-intense system (4.1 MJ Kg-1) compared to CT (6.5 MJ Kg-1) and RT (6.4 MJ Kg-1) systems respectively.

3.4.2.4. Net Energy

Net energy represents the difference between the output energy to the energy input used to produce it [50]. Therefore, net energy values are highly influenced by both the input and the output energy. The sustainability of the system will depend on the production of higher energy output and to reduce as much as possible the energy input. We reported an average net energy of 143342.5 MJ ha-1, which varied significantly across years and tillage systems. This average value was three folds higher than the one reported by Kazemi i.e. [12] due to much higher gross energy output obtained in the present study using the same amount of input energy. The highest net energy value of soil tillage systems was obtained in NT and the lowest net energy in RT (Table 5). On average, 147556.6 MJ ha-1, 146013 MJ ha-1 and 136457.8 MJ ha-1 were reported for NT, CT and RT respectively. Across the study years, the highest net energy value (212443.7 MJ ha-1) was reported in 2014 while the first year gave the lowest net energy (57980.6 MJ ha-1). Net energy values under the study years were in order 2014>2015>2016>2013>2012>2011.

3.4.2.5. Energy Profitability

On average, we reported an energy profitability value of 10.9 MJ ha-1 at the end of the study year (Table 5). The analysis of the results indicate that energy profitability increased with the decrease in management intensity and was highly correlated with biomass productivity. This was previously observed at the same study site for wheat production [18]. Evident to that is the highest energy profitability (15.9 MJ ha-1) that was reported in 2014 when the highest straw yield was obtained, followed by 2015 (12.9 MJ ha-1) with the highest grain yield. First year was the least energy profitable (4.5 MJ ha-1) among years with significant lower biomass yield (grain and straw). Among tillage systems, the results indicate that the NT system was more profitable (+31%) than CT and RT. Their values were 13.7 MJ ha-1, 9.6 MJ ha-1 and 6.3 MJ ha-1 for NT, CT and RT respectively (Table 5). Barut i.e. [51] reported an average energy profitability of 7.26, 7.59 and 7.78 for NT, CT and RT systems respectively for corn silage production in Turkey.

3.4.2.6. Human Energy Profitability

Human energy profitability was calculated based on manpower and its energy equivalent used to produce the output. In the modern agriculture, the use of manpower was reduced to the minimum that is enough to operate the farm machinery in faba bean production. Therefore, the reduction in field operation in NT system will resulted in higher human energy profitability per hectare. As reported in previous study [18], energy used in manpower was reduced by almost 65% in NT, as much of this energy was used to conduct the primary and the secondary tillage in both RT and CT systems. In this study, with high output energy and lower human labor, NT gave much higher human energy profitability with an average of 66906.8 MJ h-1 compared to RT (22927.8 MJ h-1) and CT (23852.4 MJ h-1) (Table 5). Similar to other energy indexes, there was large year-to-year variation for human energy profitability. In general, human energy profitability followed the same trend of energy profitability with the highest human energy profitability being reported in 2014 (52153.5 MJ h-1) and the lowest was reported in 2011 (17819.2 MJ h-1).

CONCLUSION

We tested the hypothesis of whether conservation tillage practice is a viable option for sustainable faba bean production under rainfed conditions. The analysis of results revealed that no-tillage gave better or comparable yield and quality results compared to the conventional one. However, the agronomical parameters exhibited year-to-year variation due to weather conditions indicating the importance of inter-annual variation of rainfall and temperatures during the growing season, especially in the dry regions. Energy analysis indicate that no-tillage system resulted in 29% less fossil fuel consumption than conventional system without a significant difference in grain yield. To the best of our knowledge this is the first peer-reviewed study, regarding the energy analysis in rainfed faba bean production, to include the energy stored in faba bean straw in the analysis. Therefore, much higher output energy is expected in this study compared to those in the literature. The analysis of energy indexes values indicate that, despite the fact that higher energy output was obtained under conventional tillage, the no-tillage system was the most energy profitable, less energy-intense, highest energy productive and more efficient in the use of energy. The key agronomic and environmental benefits of no-tillage in rainfed faba bean production are its ability to compete with the conventional system with much lower energy input. However, we should pare in mind that the application of no tillage system requires an increase in the synthetic chemicals use (i.e. Glyphosate in pre-sowing) with negative repercussions from an environmental point of view. Results from this study indicated that faba bean (Vicia faba L.) can be adapted to low rainfall regions using no tillage soil management. The adaption of this system can be a valuable option in crop production, compliance with sustainability criteria.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

No Animals/Humans were used for studies that are base of this research.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENT

Declared none.